Headquartered in Zwevegem, Belgium, NV Bekaert SA has remained one of the industrial partners directly involved in the ECO2FUEL project. For several years, Bekaert has been an active component supplier of metal-based porous transport layers (PTL) and gas diffusion layers (GDL) for water electrolysis. Its strong ambition toward innovation and process know-how poises Bekaert to continue leveraging technology to create adjacent technologies and optimized applications.

In the ECO2FUEL project, Bekaert contributes to the following areas:

– Investigate proposed electrolyzer design possibilities

– Develop Ni PTL continuous roll manufacturing process

– Understand the importance of optimized PTL/GDL designs

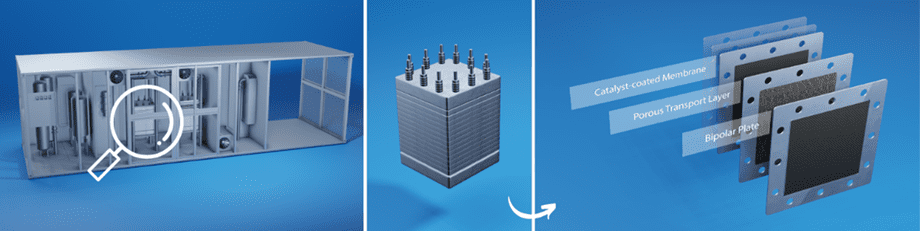

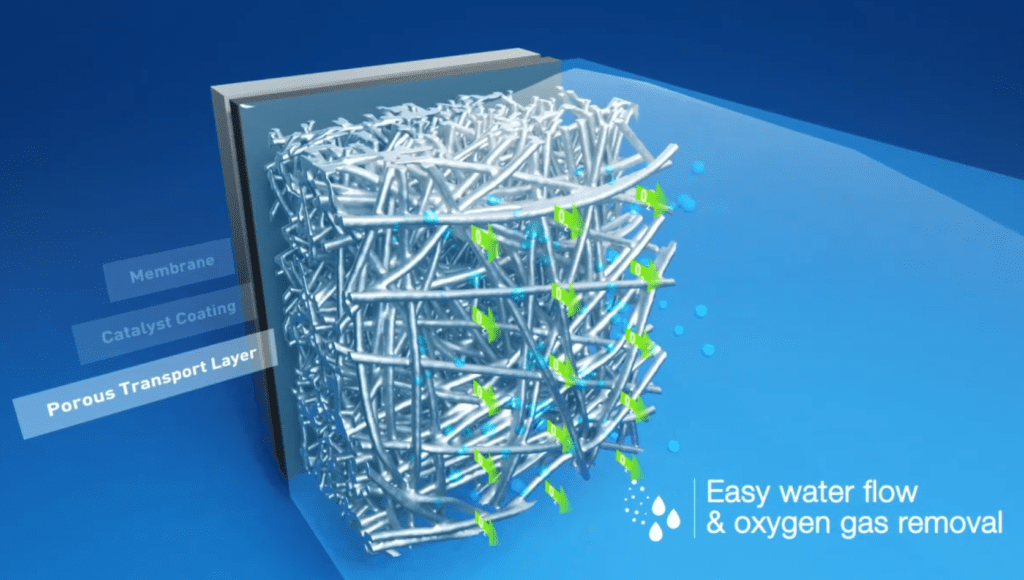

In terms of electrolysis cells, PTL/GDL is one of the most critical components of multiple functionalities facilitating the electrolysis process, including:

– Efficient, homogeneous mass transport and gas diffusion

– High electrical and thermal conductivity

– Low contact resistance for high interaction (between the catalysts and exchange membrane)

One challenge the project presents demands the need for PTL/GDL to guarantee longevity and durability. Bekaert achieves this through optimal mechanical properties and improved resistance to corrosion. Although, for example, the proposed electrolyzer concept deposits the catalyst on the electrodes, the proposed PTL/GDL design facilitates a simplified and homogeneous coating. Therefore, an optimal product design and an efficient manufacturing process were proven essential to the proposal’s overall success.

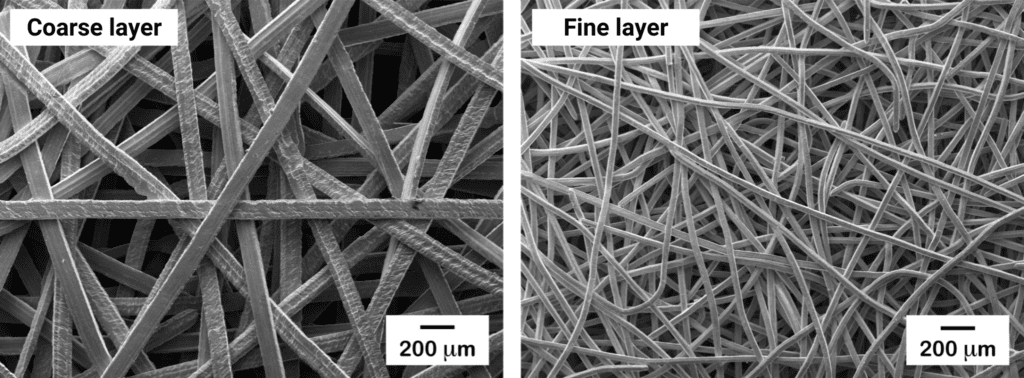

As part of the ECO2Fuel project, Bekaert’s role in providing PTL/GDL designs was geared toward identification and evaluation for use as prototypes and upscaling. The manufacturing process for metal-based PTL/GDL consists of 3 steps:

– Manufacturing of metallic fibers (nickel anode)

– Randomly distributed/oriented green state porous fiber structure

– Fiber binding heat treatment

Throughout the manufacturing process, Bekaert has developed and achieved methods to manipulate various aspects of metal fibers (i.e., diameter, porosity, thickness, multilayers, etc.). This success is due to Bekaert’s endeavor to test numerous production possibilities to identify the most efficient design possible. As a result, Bekaert’s design provides the foundation for the ECO2Fuel project to expand the PTL/GDL technology to a larger scale.

As part of their effort to optimize the operation even further, Bekaert continues investigating the impact of the catalyst coating process on the PTL (and vice versa). Typically, the application process involves the application of the coating directly onto the exchange membrane. However, the porous nature of the metallic structure poses unique challenges during the catalyst application. Due to the material’s inherent difficulties, this procedure requires the application of ink through a film coating or spray process. Bekaert utilizes lab-scale testing to investigate the impact on coating processes and identify optimization possibilities.

Looking toward the future, Bekaert plans to develop the manufacturing process further to supply Ni PTL in a continuous format. Although it is manufacturing large sheets, Bekaert intends to create a continuous structure to simplify the downstream process cost-efficiently. By developing such a process, Bekaert can successfully streamline the catalyst coating application process and reduce PTL scrap.

Reference: Currento® porous transport layer for hydrogen production – Bekaert.com