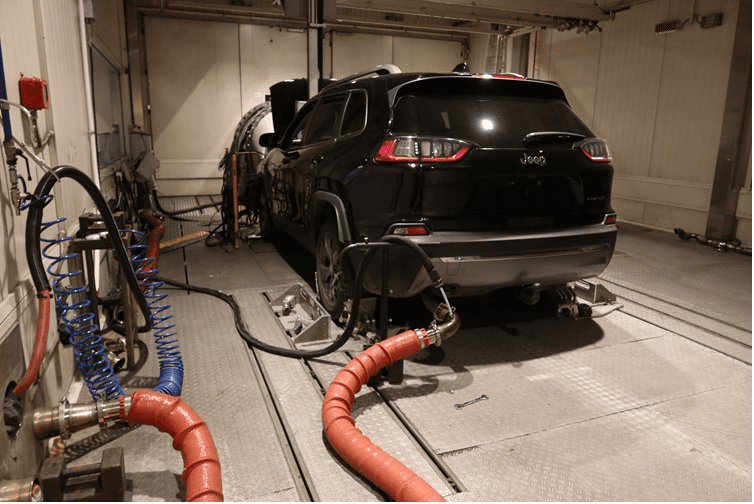

In ECO2Fuel, CRF provide crucial information about the features of the diesel -alcohol blend produced within the project, helping the partner to calibrate this formulation in order to obtain a product that is compliant with the current standard in this field.

Alcohols have an interesting potential as blending components for diesel fuels: if their production derives from renewable sources, they could contribute toward increasing the renewable fraction of these fuels and reducing their environmental impact.

The major limitations in fueling this blends in a diesel engine are the poor miscibility between alcohol and diesel, which leads to a phase separation, but also the lower flash point, cetane number, kinematic viscosity and energy content and higher heat of vaporization. As a consequence of their lower polarity, short-chain alcohols depict worse blending stability than alcohols of three or more carbons (propanol and higher).

To stabilize alcohol-diesel blends and to ensure fuel homogeneity under all temperature conditions, it is indispensable the use of additives as alcohol with longer chain (cetanol and dodecanol) or the biodiesel (FAME).

CRF performed a wide literature research to obtain an experimental matrix of possible diesel-alcohol (ethanol and propanol, the main products of the project) blends with different content of additives, in order to evaluate the most suitable and stable blend in all the conditions.

These stability tests will be performed by UPV and the blends that show the most interesting features will be tested in CRF, in order to assess their compliance with the standard reference norm EN590: “Automotive fuels – Diesel – Requirements and test methods” the current standard for all automotive diesel fuel sold in the European Union member states and other European countries.