The electroreduction of CO2 bears several challenges, one of which is that the central reactant is in the gas phase. Due to that, when using conventional electrodes, the conversion of CO2 to valuable chemicals and fuels would proceed at a slow rate, rendering the process uneconomical.

The low concentration of CO2 in the electrolyte caused by its negligible solubility limits the mass transport at the electrode surfaces. To cope with this challenge, electrodes with an engineered porous structure were developed that drastically enhance the contact between the electrode, CO2 and the electrolyte; the three-phase boundary (TPB).

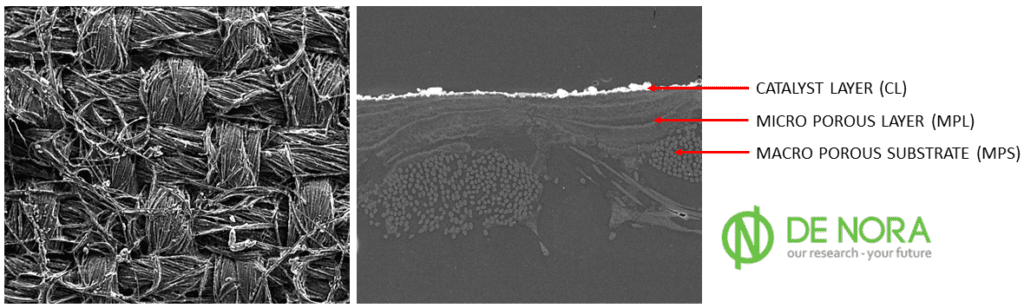

These enhanced electrodes, also known as gas diffusion electrodes (GDE), with improved mass transport kinetics, consist of a Macro Porous Substrate (MPS), a Micro Porous Layer (MPL) and the Catalyst Layer (CL), the latter consisting of a CO2 reduction catalyst and a polymeric binder.

Among varying many other parameters through which the GDE can be optimized to facilitate the electroreduction of CO2 efficiently, altering the porosity, hydrophobicity, and thickness of all three components display the most important ones.

“It’s important to design the right GDE structure in order to avoid the flooding and therefore loss of stability and activity” says Luca Riillo, Junior Researcher at De Nora.

In the ECO2Fuel project, we aim to provide an optimized GDE with high stability, performance, and selectivity toward liquid e-fuels.