The 20th International Conference on Carbon Dioxide Utilization (ICCDU-XX) is set to be a significant event for the discussion and advancement of sustainable technologies. Among the distinguished speakers, De Nora, an Italian multinational company listed on the Euronext Milan Stock Exchange, will take the stage to deliver a keynote lecture on their role in the energy transition and CO2 electrochemical reduction. This article provides an overview of De Nora’s involvement in the field, highlighting the projects SELECTCO2 and ECO2Fuel, as well as introducing the presenter, Daniela Galliani.

De Nora is a renowned leader in electrochemistry and specializes in providing sustainable technologies. With a century of experience in the industry, the company has become the world’s largest supplier of high-performing catalytic coatings and insoluble electrodes for various electrochemical and industrial applications. Additionally, De Nora is a leading provider of equipment, systems, disinfection, and filtration solutions for water and wastewater treatment, emphasizing their commitment to promoting environmental stewardship.

In line with the global shift towards a greener economy, De Nora has embraced the challenge of the energy transition by focusing on two main approaches: hydrogen production via electrolysis and CO2 electrochemical reduction. Through their innovative technical solutions, De Nora aims to contribute to the production of hydrogen, which holds significant potential as a future energy carrier and an essential component of the green economy.

For hydrogen production, De Nora offers industrial-level solutions such as DSA® Electrodes for Alkaline Water Electrolysis (AWE), Electrolysis Cells, and Gas Diffusion Electrodes (GDE) for fuel cells. By participating in large-scale projects, De Nora plays a crucial role in implementing hydrogen as a reactant for future energy carriers and fuels.

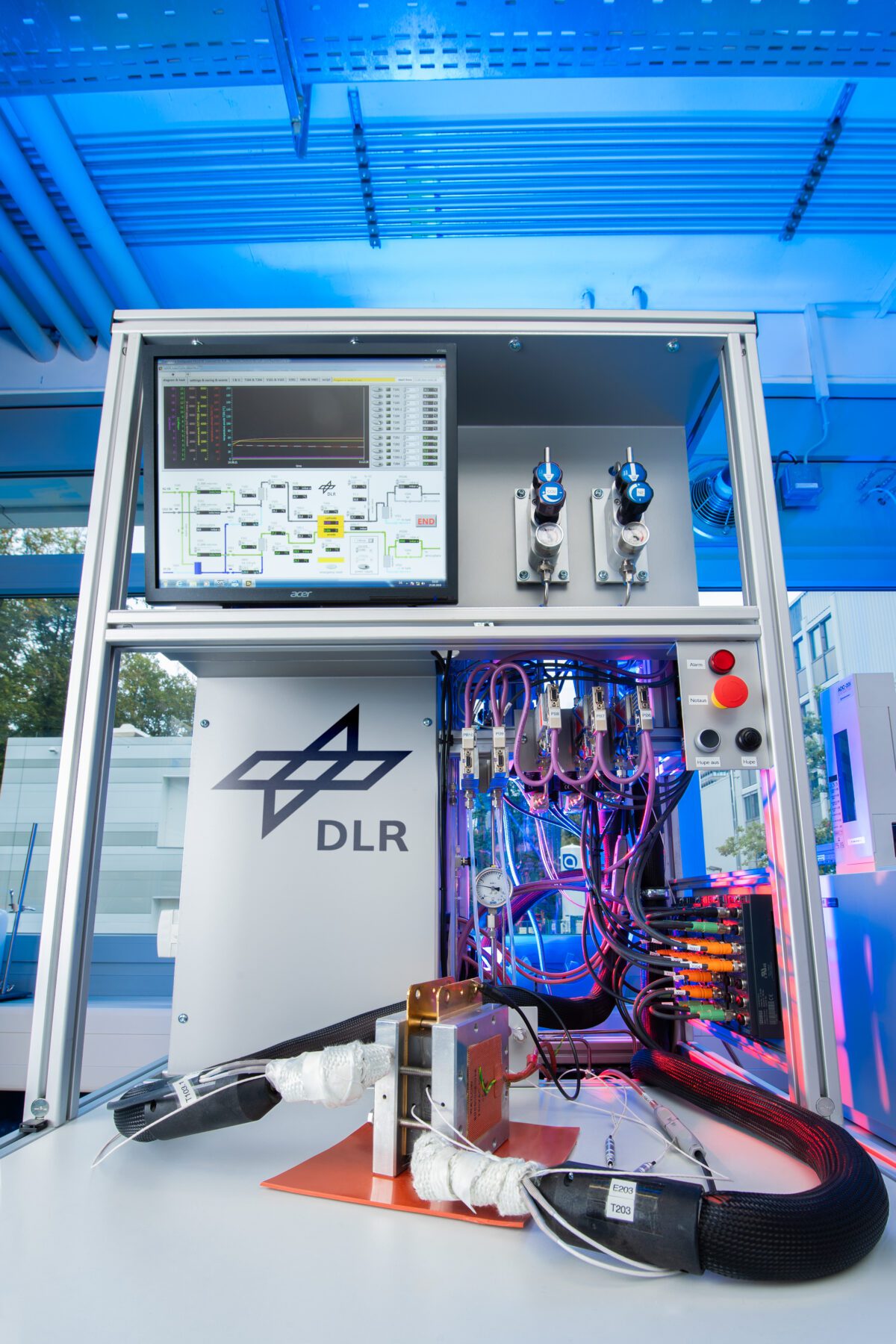

Furthermore, De Nora is actively involved in the study and development of CO2 electrochemical reduction through collaborations in financed projects. The company’s research and development teams across three different sites, namely the United States, Italy, and Germany, are currently working on this exciting technology. Their ambitious goal is to achieve efficient direct electrochemical conversion of CO2 into valuable chemicals or fuels, thereby contributing to the reduction of greenhouse gas emissions and the utilization of carbon dioxide as a resource.

During the ICCDU 2023 keynote lecture, De Nora will shed light on their efforts and achievements in the field of CO2 electrochemical reduction. They will discuss two significant projects, SELECTCO2 and ECO2Fuel, which showcase their commitment to technological innovation and sustainability.

The SELECTCO2 project focuses on exploring and developing efficient methods for the direct electrochemical conversion of CO2 into valuable chemicals or fuels. By leveraging their expertise in electrochemistry and electrodes, De Nora aims to drive advancements in this area, ultimately enabling a more sustainable and circular carbon economy.

The ECO2Fuel project, on the other hand, aims to tackle the challenge of CO2 utilization by converting it into a carbon-neutral fuel. De Nora’s contributions to this project will be highlighted during the keynote lecture, emphasizing their dedication to finding practical solutions to the global climate crisis.

The keynote lecture will be delivered by Daniela Galliani, who currently serves as the Program Leader within De Nora’s Energy Transition and Hydrogen (ETH) Department. With a background in chemistry and a Ph.D. in Physical Chemistry, specializing in organic electronics with thermoelectric applications, Galliani brings a wealth of knowledge and expertise to her role.

In her previous position as a researcher in De Nora’s R&D team, Galliani focused primarily on the electrochemical reduction of CO2. Now, as the Program Leader, she manages activities related to diaphragms for Alkaline Water Electrolysis (AWE) and coordinates the company’s research and development activities in the Anion Exchange Membrane Water Electrolysis (AEM WE) field.